Roof Load Calculations for Solar: Engineer’s Guide 2026

Roof Load Calculations for Solar: Engineer’s Guide to Safe Installations

Introduction

Roof load calculations for solar installations determine whether your project moves forward or stalls in permitting. Every solar installer faces this critical question: can the roof handle the weight? When engineers analyze structural capacity, they examine four essential load types that ensure safe, code-compliant installations.

Modern solar systems add approximately 2-4 pounds per square foot to a roof. However, this weight combines with snow, wind, and seismic forces to create complex loading scenarios. Understanding how structural engineers approach roof load calculations for solar helps installers avoid costly delays and redesigns.

Why Roof Load Analysis Prevents Project Delays

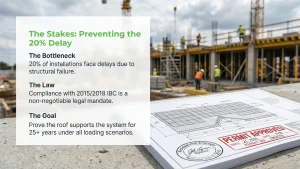

Approximately 20% of solar installations experience delays due to structural issues. When roof load calculations for solar reveal inadequate capacity, installers face expensive redesigns and frustrated customers. Therefore, getting the structural analysis right from day one protects both your reputation and revenue.

Most residential roofs built after 1970 can support at least 20 pounds per square foot. Nevertheless, existing dead loads often consume much of this capacity before adding solar equipment. As a result, professional engineering analysis becomes essential for every project.

Understanding Dead Load in Solar Installations

Dead load represents the permanent weight on your roof. For solar projects, this includes panels (40-50 pounds each), mounting rails, clamps, and electrical components. Consequently, when you divide total system weight by coverage area, you get distributed load—typically 2-4 pounds per square foot.

However, this weight isn’t actually distributed evenly. Instead, mounting brackets create point loads at rafter attachment points. For example, if you attach to every other rafter, you’ve doubled the load on those specific structural members.

Common roofing materials already contribute significant dead load:

- Asphalt shingles: 15 pounds per square foot

- Clay tiles: 27 pounds per square foot

- Metal roofing: 5-10 pounds per square foot

Live Load Considerations for Solar Arrays

Live loads are temporary forces that roofs must support. These include maintenance workers (calculated at 20 psf) and, more critically, snow accumulation. According to ASCE 7-16 standards, engineers use ground snow load data adjusted for roof slope, exposure, and thermal conditions.

Furthermore, solar panels can create drift zones where snow accumulates heavily. The panels provide slippery surfaces, but snow piles up at panel edges and mounting equipment. Engineers must account for these concentrated loads in their calculations.

Wind Load: The Uplift Challenge

Wind creates both downward pressure and upward lift on solar arrays. Notably, the uplift forces often become the most critical concern. When wind flows under solar panels, it creates significant suction attempting to pull the array off the building.

ASCE 7-16 introduced specific pressure coefficients for rooftop solar based on extensive testing. These calculations consider:

- Local wind velocity

- Building height and exposure

- Roof geometry

- Panel positioning

Consequently, attachment points must resist both downward dead weight and upward wind loads. In high-wind zones, this requires additional mounting points or reinforced attachment methods.

Roof Load Calculations for Solar: Seismic Load Requirements Across the United States

Seismic loads matter beyond California. In fact, ASCE 7-16 Section 13.3 treats solar arrays as non-structural components requiring seismic design across much of the United States. The weight of your solar system directly impacts these calculations.

Engineers ensure arrays withstand lateral movement during earthquakes without detaching or causing structural damage. In high seismic zones, this might require:

- Specific attachment patterns

- Flexible wiring methods

- Impact-resistant barriers

How Engineers Calculate Roof Capacity

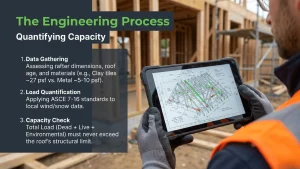

Professional structural analysis follows a systematic process. First, engineers gather existing structural data including original building plans, rafter dimensions, roof age, and current materials. If plans aren’t available, site surveys provide direct measurements.

Next comes load quantification. Engineers total all solar component weights for dead load calculations. They determine live loads from location-specific building codes. Wind loads require formulas accounting for building exposure. Seismic loads come from regional maps and building mass calculations.

Finally, engineers compare combined loads against roof structural capacity. The total load (dead + live + environmental) must stay within capacity with appropriate safety factors. Most jurisdictions require Professional Engineer stamps on these calculations.

Solutions When Roofs Don’t Meet Requirements

Not every roof supports solar panels in its current state. Fortunately, engineers have several options:

Reinforcement Strategies:

- Adding members to existing rafters

- Replacing compromised structural elements

- Redistributing loads through modified layouts

- Switching to lighter panel systems

Sometimes ballasted systems that don’t penetrate roofs provide the most cost-effective solution. Other times, strategic reinforcement of key members opens up the entire roof. Experienced engineering firms evaluate these options and recommend practical paths forward.

Roof Load Calculations for Solar: Building Code Compliance Is Non-Negotiable

Recent International Building Code editions (2015 IBC and 2018 IBC) include specific solar requirements. The code mandates that construction documents clearly indicate dead loads for panels, support systems, and ballast. Additionally, roof structures must accommodate applicable live loads even with solar panels present.

These aren’t suggestions—they’re legal requirements. Jurisdictions enforce codes through permitting processes. When your calculations don’t meet requirements, you’re stuck until they do. This is exactly why partnering with experienced solar engineers makes such a difference.

The Bottom Line for Solar Professionals

Roof load calculations for solar determine project feasibility and permitting success. Understanding the four load types—dead, live, wind, and seismic—helps you identify potential issues during site surveys. Moreover, this knowledge enables informed conversations with engineers and realistic customer expectations.

The principle is straightforward: prove the roof safely supports the solar system for 25+ years under all credible loading scenarios. That proof comes from professional engineering analysis using established building codes and standards.

Stop Structural Delays from Killing Your Solar Projects

EnergyScape Renewables delivers comprehensive roof load calculations for solar installations with PE stamps in all 50 states. Our unique 24-hour turnaround keeps projects on schedule while ensuring first-time approval rates.

Our structural engineers understand real-world installer challenges: tight timelines, complex roof conditions, and demanding AHJ requirements. From initial assessment to final PE stamp, our end-to-end services cover every structural detail.

Visit EnergyScape Renewables today and discover how overnight engineering transforms project timelines. When you need calculations done right and done fast, we deliver.

Meanwhile, streamline your entire workflow with Sunscape’s CRM platform. Track structural approvals, manage permitting timelines, and organize every project detail in one place.

Explore Sunscape Solar and see how our platform integrates seamlessly with your engineering workflow.

sjayakanth@energyscaperenewables.com