Solar Site Survey Best Practices to Avoid Delays

Solar Site Survey Best Practices: What Your Engineer Needs Before Design Starts

Solar site survey best practices: Poor site data creates expensive problems. When your engineer receives incomplete measurements or unclear electrical panel photos, your project timeline stretches by days or weeks. Design rework costs money, frustrates clients, and ties up your team on fixable problems.

Solar site survey best practices start with understanding what your design team actually needs. This guide shows solar installers and EPCs exactly how to collect accurate site data the first time, eliminating delays and protecting your margins.

Why Quality Solar Site Surveys Matter in 2026

The solar installation industry has changed. Customers expect proposals within 48 hours. Authorities Having Jurisdiction (AHJs) scrutinize permit applications more carefully. Your site survey process either supports fast, accurate design or becomes your biggest bottleneck.

Projects with comprehensive initial surveys experience 60% fewer change orders during installation. That difference directly impacts your profitability and customer satisfaction.

Modern solar project management requires precision from day one. Let’s break down the critical components.

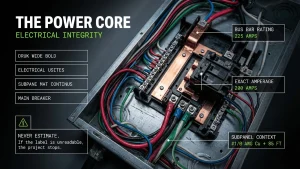

Essential Electrical Panel Assessment Data

Your electrician and engineer need clear, detailed information about existing electrical service. Here’s your complete checklist:

Main Service Panel Requirements

- Exact amperage rating (check the main breaker label directly)

- Bus bar rating (often different from main breaker capacity)

- Available spaces for new breakers

- Clear photos of panel label showing manufacturer and model

- Current breaker inventory with individual amperage ratings

- Panel condition including any corrosion or damage

Subpanel Information Needed

- Location relative to main panel

- Amperage and bus bar ratings

- Feeder wire size and type

- Measured distance from main service

Service Entrance Details

- Meter location and accessibility

- Service wire size entering the building

- Overhead or underground service designation

- Utility company markings or meter numbers

Never estimate electrical specifications. Take photos of every label on that panel. Your solar design team will work faster with accurate data.

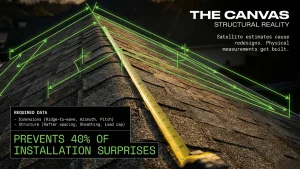

Critical Roof Measurements and Condition Assessment

Satellite imagery helps with initial estimates, but final design requires precise measurements:

Required Dimensional Data

- Ridge-to-eave measurements for each roof plane

- Width of each installation area

- Pitch measurements using inclinometer app or pitch gauge

- Azimuth readings for each plane

- Height from ground to roof edge

Roof Condition Documentation

- Roofing material type and estimated age

- Condition of shingles, tiles, or membrane

- Locations of all penetrations (vents, chimneys, skylights)

- Evidence of previous repairs or damage

- Photos of unusual features or obstacles

Structural Considerations

- Visible sagging or structural concerns

- Rafter spacing if accessible from attic

- Sheathing type when visible

- Load-bearing capacity concerns

According to the Solar Energy Industries Association (SEIA), proper structural assessment during initial surveys prevents 40% of installation-day surprises.

Comprehensive Shading Analysis Requirements

Shading analysis directly impacts project economics. Your solar site survey best practices must include:

Permanent Shade Sources

- Trees with species, height, and proximity to roof

- Neighboring structures

- Chimneys or roof features

- Power lines or utility poles

Time-Stamped Documentation

Take photos from multiple angles showing potential shade sources. Note the time and date. Use shading analysis tools like Solmetric SunEye or Aurora’s mobile app to capture actual shade data throughout the day.

Document seasonal considerations. Deciduous trees might not matter in winter but could significantly impact summer production.

Site Access and Installation Logistics

Your installation crew needs this information before arriving on-site:

- Gate widths and access points

- Distance from truck parking to work area

- Ladder placement options

- Material staging areas

- HOA restrictions or requirements

- Underground utility locations (always call 811)

Professional Photo Documentation Standards

Blurry photos waste everyone’s time. Follow these standards for every solar site survey:

Required Photo List

- Wide shot of entire property showing all roof planes

- Close-up of each roof section where panels will install

- Electrical panel with door open showing all breakers and labels

- Meter and service entrance

- Attic space when accessible

- Ground-mount locations showing terrain and orientation

- Any obstacles or concerns

Photo Quality Requirements

- Take photos in good lighting conditions

- Keep all images in focus at high resolution

- Include measuring tape or reference object for scale

- Capture label text clearly without glare or blur

- Take multiple angles of complex areas

Common Site Survey Mistakes That Cause Design Delays

Mistake #1: Estimating Instead of Measuring

“About 30 feet” becomes 26 feet during installation. Your module layout doesn’t fit, and you’re redesigning on-site with frustrated crews.

Mistake #2: Forgetting About Setbacks

AHJ requirements for roof edge clearances vary by jurisdiction. Know your local codes before assuming you can use the entire roof plane.

Mistake #3: Incomplete Electrical Information

Missing bus bar ratings or unclear service wire sizes force return visits. Collect complete data the first time.

Mistake #4: Ignoring Future Shading

Small trees grow. Document tree species and growth rates to predict future shading issues accurately.

Mistake #5: Poor Team Communication

Your surveyor noticed something unusual but didn’t document it. Three days later when the engineer has questions, nobody remembers the details.

Creating Your Standardized Site Survey Checklist

Build a checklist your team uses on every job:

- Main panel amperage and bus rating verified

- All roof planes measured and photographed

- Pitch and azimuth readings recorded

- Shading analysis completed

- Service entrance documented

- Access and staging areas assessed

- Special conditions or concerns noted

- All required photos uploaded to project folder

Consistency eliminates errors and accelerates your solar engineering design process.

Technology That Improves Survey Accuracy

Modern tools make surveys faster and more accurate for solar installers:

Mobile Apps and Digital Tools

- Digital pitch finders for accurate roof measurements

- Compass apps for azimuth readings

- Photo markup tools for annotations

- Cloud-based data collection forms

Advanced Equipment

For larger commercial projects, aerial photography provides comprehensive roof documentation without safety risks. Dedicated shade analysis devices capture actual sun path data instead of relying on estimates.

Choose tools your team will use consistently. Expensive equipment sitting in the truck doesn’t improve your solar site survey best practices.

When to Consider Professional Survey Services

Not every solar company has bandwidth to conduct thorough site surveys. You might focus on sales while your installation crew stays booked solid.

Professional surveyors bring standardized processes, proper equipment, and experience across thousands of sites. They know what engineers need because they work with design teams daily.

According to National Renewable Energy Laboratory (NREL) research, outsourcing site surveys can reduce project timelines by 25% for growing installation companies.

Streamline Your Solar Site Survey Process Today

Quality site surveys aren’t about checking boxes. They’re about giving your engineering team exact data needed to design systems that install smoothly and perform as promised.

Ready to eliminate survey bottlenecks and design delays?

At Sunscape, we help solar installers and EPCs streamline operations through expert engineering support and turnkey design services. We understand the challenges you face daily.

For companies scaling without hiring additional survey staff, EnergyScape Renewables dispatches experienced local surveyors nationwide—covering all 50 states. We deliver comprehensive site data your engineers need, formatted exactly how they want it, so design work starts immediately.

Let’s discuss your survey process. Explore our full range of solar support services or learn how our site survey teams become an extension of your operations.

Stop losing days to incomplete site data. Get it right the first time with proven solar site survey best practices.

Frequently Asked Questions About Solar Site Surveys Best Practices

What’s the most critical data point in a solar site survey?

Electrical panel specifications, including exact amperage and bus bar ratings, are most critical. Incorrect electrical data causes the most design delays and permit rejections.

How long should a comprehensive residential site survey take?

A thorough residential solar site survey typically takes 45-90 minutes, depending on property complexity and roof accessibility.

Can I use satellite imagery instead of physical roof measurements?

Satellite imagery helps with initial estimates but isn’t accurate enough for final design and permitting. Physical measurements are required for permit-ready drawings.

What shading percentage makes a roof unsuitable for solar?

Generally, locations with less than 4 hours of unshaded peak sun aren’t economically viable. However, modern optimizers and microinverters have improved tolerance for partial shading.

Do I need professional survey services for every project?

Not necessarily. Professional services benefit companies scaling quickly, handling complex commercial projects, or lacking internal survey capacity. Many residential installers successfully conduct their own surveys using proper checklists and equipment.

sjayakanth@energyscaperenewables.com