Microinverters vs String Inverters: 2026 Guide for Solar Installers

Microinverters vs String Inverters: The 2026 Decision Guide for Solar Installers

Choosing between microinverters vs string inverters is one of the most critical decisions you’ll make for your solar installations in 2026. With NEC 2023 rapid shutdown requirements reshaping the landscape and cost pressures impacting every project, understanding when to use microinverters versus string inverters directly affects system performance, customer satisfaction, and your bottom line.

Both inverter technologies work effectively, but the question isn’t which one is universally better. Instead, you need to match the right inverter type to each specific project’s requirements—considering roof complexity, shading patterns, budget constraints, and long-term performance goals.

Understanding the Cost Difference Between Microinverters and String Inverters

When comparing microinverters vs string inverters, cost drives initial decisions. String inverter systems run $750-$1,250 for 5kW residential installations, while microinverters cost $1,500-$3,000 for equivalent systems.

However, upfront pricing doesn’t reveal the complete picture. String inverters carry 10-12 year warranties, while microinverters offer 25-year coverage matching panel lifespan. Over the system’s lifetime, replacement costs narrow this gap significantly.

Moreover, failure rate data strongly favors microinverters. Industry tracking shows microinverters fail at just 0.0551% (5.5 per 10,000 units), while string inverters fail at 0.89% (89 per 10,000 units). That 16x difference directly impacts warranty callbacks and customer satisfaction.

How NEC 2023 Rapid Shutdown Requirements Changed the Game

The debate around microinverters vs string inverters shifted dramatically with NEC 2023 code changes. Rapid shutdown requirements now mandate that PV systems reduce conductor voltage to 30 volts within 30 seconds outside the array boundary and 80 volts inside it, as specified in NEC Section 690.12.

Consequently, microinverters meet this requirement inherently. They convert DC to AC at each panel, naturally limiting voltage throughout the system. In contrast, string inverters need additional power optimizers or specialized rapid shutdown devices to achieve compliance—adding equipment costs and installation complexity.

That said, UL 3741-listed systems provide an alternative compliance path. Some string inverter manufacturers now offer complete PV Hazard Control Systems (PVHCS) meeting code requirements without module-level power electronics on every panel. For large, unshaded arrays, this can restore string inverters’ cost advantage while maintaining full compliance.

When Microinverters Are the Right Choice

Complex roof layouts represent ideal scenarios for microinverters. Multiple roof planes, dormers, chimneys, or varied panel orientations allow each module to operate independently. Consequently, one shaded panel doesn’t reduce entire string performance.

Production data confirms this advantage. In partially shaded conditions, microinverters deliver 5-25% higher output compared to string systems, based on field studies from EnergySage and monitoring platforms.

Additionally, panel-level monitoring provides significant operational benefits. When customers report underperformance, you identify the exact problematic panel without dispatching technicians.

Furthermore, future expansion becomes straightforward. Adding panels simply means adding microinverters—no sizing calculations or string reconfiguration required.

Where String Inverters Still Make Sense

Despite microinverter advantages, string inverters remain optimal for many installations. Straightforward residential projects on unshaded roofs with consistent sun exposure benefit from efficient power conversion at lower costs.

Installation speed significantly affects profitability. A single ground-level string inverter installs faster than 20+ rooftop microinverters, improving crew productivity.

Moreover, maintenance accessibility matters. String inverters are accessible from ground level—no roof work, safety concerns, or weather delays.

For commercial projects with large, unshaded roof areas, string inverters paired with power optimizers provide ideal balance—module-level optimization without full microinverter pricing.

The Decision Framework: Microinverters vs String Inverters

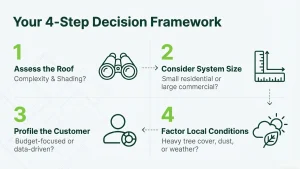

When choosing between microinverters vs string inverters, follow this systematic approach:

Step 1: Assess the Roof Walk the site, photograph all roof planes, and document orientation, shading patterns, and complexity. Multiple planes, partial shade from trees or chimneys, or east-west configurations indicate microinverters. Simple, south-facing roofs with full sun suggest string inverters.

Step 2: Consider System Size Smaller residential systems under 8kW may not justify microinverter premiums unless shading is significant. Larger residential systems (10kW+) and commercial installations benefit more from microinverters’ granular optimization capabilities.

Step 3: Profile Your Customer Tech-savvy homeowners who monitor their systems daily appreciate microinverters’ detailed panel-level data. Budget-conscious customers with simple roofs get excellent value from well-designed string inverter systems.

Step 4: Factor Local Conditions In regions with heavy tree cover, frequent weather changes, or air quality issues (dust, pollen), microinverters’ independent panel operation provides superior long-term performance and reduced maintenance needs.

Real-World Performance: What the Data Shows

Field data from thousands of installations reveals clear patterns. Microinverter systems in partially shaded conditions consistently outperform string systems by 5-25%, according to monitoring platforms and installer reports.

Similarly, warranty claim rates tell an important story. With microinverter failure rates at 0.0551% versus string rates at 0.89%, service call frequency decreases dramatically—translating to dozens fewer warranty visits annually for installers managing 100+ systems.

What This Means for Your Solar Business in 2026

The solar market continues maturing with increasingly sophisticated customer questions. Solid technical justification for inverter recommendations builds trust and closes deals.

With microinverter failure rates running 16x lower than string inverters, you’ll handle fewer service calls and create happier customers. That word-of-mouth marketing delivers measurable value in competitive markets.

Nevertheless, don’t overlook string inverters for appropriate applications. Smart installers match technology to project requirements, optimizing both performance and profitability.

Get Expert Engineering Support for Any Inverter Configuration

Whether you’re designing systems with microinverters, string inverters, or hybrid approaches, proper engineering makes the difference between projects that pass inspection easily and those requiring multiple revisions. That’s precisely where EnergyScape Renewables provides critical support.

We deliver comprehensive solar engineering, design, and PE stamping services for both microinverter and string inverter architectures. Our team ensures your systems meet NEC 2023 rapid shutdown requirements, optimize performance for specific site conditions, and pass inspections the first time.

With 24-hour PE stamping available across all 50 states and deep expertise in both MLPE and PVHCS compliance paths, we help you complete projects faster with fewer revisions. Whether you’re tackling complex residential installations requiring microinverters or large commercial arrays using string inverters with optimizers, we bring the engineering experience your projects demand.

Visit EnergyScape Renewables to discover how our engineering services streamline your solar projects.

After finalizing system design and completing installation, efficient project management becomes essential. Sunscape Solar provides purpose-built CRM and project management software specifically for solar installers and EPCs. Track microinverter and string inverter installations, monitor system performance, manage sales pipelines, and keep every project on schedule—all from one integrated platform.

With advanced site survey tools, accurate project tracking, and seamless workflow management, Sunscape helps you handle more installations without adding administrative overhead. Whether managing 10 projects or 100, our solar-specific CRM keeps teams coordinated and customers informed throughout every installation phase.

Explore how Sunscape Solar transforms your solar project management today.

Frequently Asked Questions About Microinverters vs String Inverters

Q: Do microinverters work during power outages?

A: Most microinverters stop working during outages for safety. However, you need battery backup or hybrid inverter systems for power during blackouts, regardless of whether you choose microinverters vs string inverters.

Q: Can I mix microinverters and string inverters in one system?

A: No, you cannot combine microinverters and string inverters in a single solar array. Each system requires its own dedicated inverter architecture and cannot be mixed.

Q: How much longer do microinverters last compared to string inverters?

A: Microinverters typically last 20-25 years with warranties matching that duration. String inverters last 10-15 years, meaning you’ll likely need one replacement during your system’s lifetime.

Q: Are microinverters required for NEC 2023 compliance?

A: No, microinverters aren’t required for NEC 2023 rapid shutdown compliance. String inverters with power optimizers or UL 3741-listed PVHCS systems also meet code requirements.

Q: Which inverter type performs better in hot climates?

A: Both microinverters and string inverters handle heat effectively when properly installed with adequate ventilation. Microinverters on roofs may experience slightly higher operating temperatures, but quality units include thermal management features.

sjayakanth@energyscaperenewables.com